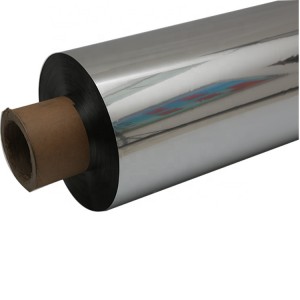

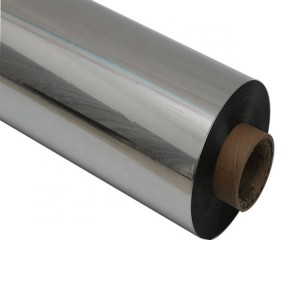

The most popular in China in 2019 silver coated pet film mpet pet for seal bag

Metalized PET Film for Flexible Packaging

Product Performance:

1. high brightness

2. strong adhesion of aluminum layer

3. high barrier of moisture and oxygen

Specification:

| Thickness | OD | Width | Length | Diameter | Inner Core |

| 6-150mic | 2.0-3.0 | ≤2350mm | 3000-36000m/r | ≤800mm | 76mm(3″),152mm(6″) |

Data Sheet:

|

NO. |

Properties |

Unit |

Value |

Test Method |

|

|

1 |

Standard Thickness |

mic |

12 |

||

|

2 |

Film Thickness Tolerance |

% |

≤ |

5 |

ASTM-D374 |

|

3 |

Tensile Strength MD |

MPa |

≥ |

200 |

ASTM-D882 |

| Tensile Strength TD |

≥ |

200 |

|||

|

4 |

Elongation at Break MD |

% |

≥ |

100 |

|

| Elongation at Break TD |

≥ |

100 |

|||

|

5 |

Heat Shrinkage(150℃/30min) MD |

% |

≤ |

1.5 |

ASTM-D1204 |

| Heat Shrinkage(150℃/30min) TD |

≤ |

0.5 |

|||

|

6 |

Wetting Tension |

mN/m |

≥ |

52 |

ASTM-2578 |

|

7 |

WVTR |

g/m2.24h |

≤ |

3.5 |

ASTM-F1249 |

|

8 |

OTR |

cm3/(m2.24h.0.1MPa) |

≤ |

15 |

ASTM-F1927 |

|

9 |

Strong adhesive strength |

% |

≤ |

20 |

— |

|

10 |

Aluminum-plate thickness |

Ω/ |

≥ |

2.0 |

— |

|

11 |

Aluminum-plate equality |

% |

± |

15 |

— |

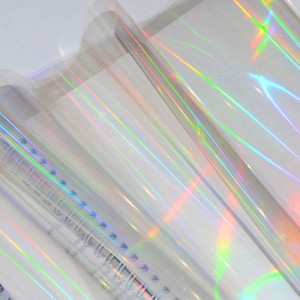

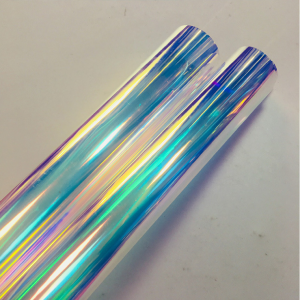

Production Process:

1. transparent film

2. metalized film

3. rewinding and slitting

4. packing

Packaging Details:

1.bubble film, to protect from collision during transportation

2.specified label, factory label or customized label without factory information

3.different types of packing ways according to roll size or customer’s request

4.wooden pallet with or without fumigation